The basic scope of the current lesson is the teaching of the fundamental practices in the sector of raw materials processing. The environmental impact of the respective processes is, at the same time, studied. The chemical and metallurgical processes, which are applied for the processing and the valorization of mineral raw materials, are correlated to high energy consumption, high consumption of regents and the extensive generation of solid and liquid residues and hazardous off gases. Aiming to the achievement of the targets of the green and circular economy, it is necessary the design of process according to the lowest energy consumption levels. At the same time, the generation of carbon dioxide should be minimized.

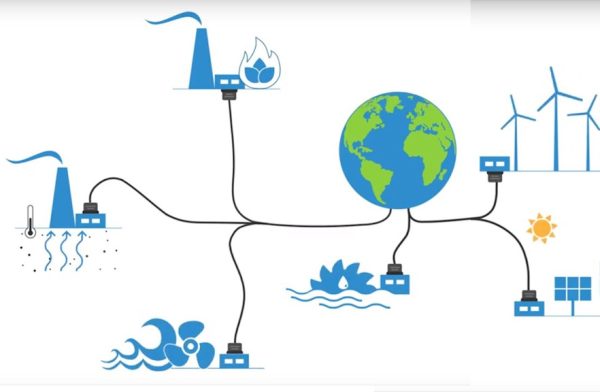

The undergraduates will be taught the methodology of energy flows reporting, analysis and management in a real industrial plant aiming to the achievement of the optimum energy consumption result. The undergraduates will be also taught the design and application of green energy sources, such as solar and wind energy, at industrial processes aiming to the elimination of fossils fuels use. The hydrogen production and storage as a raw material for the production of clean energy or as a reduction agent will be stressed out.

The fundamental principles of “life cycle assessment” methodology, which can describe the environmental impact and the evaluate the techno economic data of a process, will be also taught. Finally, various software tools (such as thermodynamic programs, simulators of metallurgical processes and “life cycle assessment tools” will be described within the framework of the course.

- Introduction. Energy demand of developed and less developed countries. Energy sources: energy production and demand issues

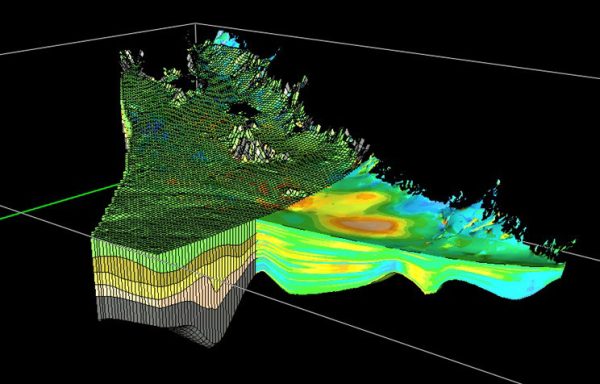

Energy flows and energy cost. Energy demand for the production of ores, concentrates and metals - Climate change and geo-environment. Exposure of greenhouse gases and impact. Impact on ecosystem, biodiversity and economy

Management actions for the accumulation of carbon dioxide in atmosphere. Carbon dioxide taxes. Exposure of greenhouse gases by the mining and metallurgical industries. Impact on the economy by the mining and metallurgical industries. - General issues on conventional plants for energy production (advantages and disadvantages). Thermoelectric, hydroelectric and nuclear power plants. Fossil fuels, technologies and environmental problems. Co-production of thermal energy. Energy recovery by rejected flows. Heat recuperators- heat generators – heat pipes-heat pumps – pinch technology.Production of metallurgical reduction agents by fossil fuels. Comparative evaluation of conventional energy sources

- Alternative and green energy sources. Solar energy: basic principles of design and installation of photovoltaics. Wind energy: basic principles of design and installation of wind turbines. Biofuels: basic principles of design and installation of biofuel plants. Hydrogen: energy carrier, storage and installations design. Use of alternative and green energies in the mining and metallurgical industry. Comparative evaluation of conventional and alternative sources of energy.

- Environmental impact and “life cycle assessment”. Definition of the scope and the target in a life cycle assessment.Data inventory and collection and quantification of energy and materials flows. Evaluation and quantification of the environmental impact using ISO indicators. Methodology for the processing and presentation of the results.