The basic scope of the course is the studying and the performance of fundamental calculations related to the processing of raw materials, intermediate products and byproducts which will be used for the production of end-products and energy. The chemical and metallurgical processes which are taking place within the framework of mining and metallurgical activities (in the laboratory, in the industry and in the environment) are directly related to the mass and energy consumption. The estimation of the mass and energy required for the realization of a physical or chemical process presents a specific significance as it determines the cost of the raw and final materials. Therefore, the mass and energy consumption is the most important indicator for the evaluation of the environmental impact and its is widely used for the quantification of this impact through the methodology of “life cycle assessment”. At the same time, the scope of the course is the comprehension of the combustion theory and the conversion of the chemical energy and the fuels to thermal energy. Various types of combustion reactors and types of fuels (coal, petroleum, natural gas, biofuels and “green mixtures”) are studied.

- Physicochemical properties and their measurement units

- Fundamental principles of the chemical and metallurgical engineering

- Chemical equations and balance

- Chemical reactions. Degree of chemical reaction progress. Degree of reactants conversation

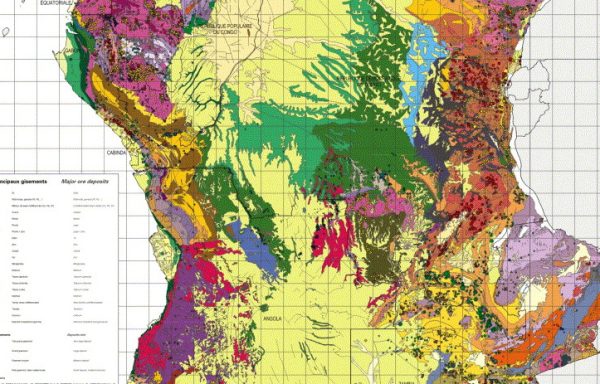

- Raw materials and final products

- Physical and chemical processes. Processes flows. Flow sheet diagrams

- Fundamental principles of mass balances. Principle of conservation of energy in open systems. Total mass balance (chemical element and chemical compound in a system without or with the realization of a chemical reaction)

- Methodology for the solving of mass balances Fundamental principles of energy balances. Basic terms. Energy balance in a closed system. Specific heat under constant pressure. Enthalpy of chemical reactions. Co-generation of heat and work

- General equation of the energy balance. Energy rate introduced in the system. Energy rate exit by the system. Energy conversion rate into the system.

- Combustion theory, conversion of fuels chemical energy to thermal energy, type of combustion reactors

- Fuels and calorific value (coal, petroleum, natural gas, biofuels and “green mixtures”)