This course introduces students in casting and forming processes. In the frame of the lectures a short review of the non-destructive testing techniques for ensuring as-cast piece integrity also takes place.

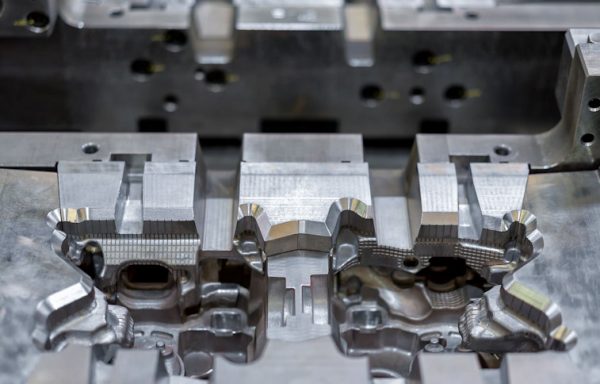

The lectures include the theoretical background for the deformation techniques. The plasticity theory sets the scientific foundation for the theoretical understanding of the forming processes and techniques. The complete process chain from casting to material (metals and alloys) processing is presented, reviewed and discussed in the lecture series. Net shape of the as-cast piece, continuous casting processes, reheating and forming operations (forging, rolling, extrusion, sheet metal forming e.g. deep drawing), both hot & warm (for the case of forging, rolling and extrusion) and cold forming operations (mainly rolling) are shown and discussed.

Physical metallurgy background starting from solidification during casting, micro- & macro- segregation, the casting defects and other related metallurgical phenomena are explicitly brought into students’ attention. Case studies for instance related to steel and aluminum production are thoroughly covered.

Taxonomy of casting and forming operations are presented as well. As the correlation of processing conditions and microstructure-properties relationships are of great significance, the students are encouraged to think creatively and critically and they are introduced in project-based learning, critical thinking and develop critical skills including working in teams and presenting abilities. Students dive in the effect of temperature and deformation that define the microstructure (including the phenomena that influence static and dynamic recrystallization, residual stresses etc.) and the material properties accordingly.

They learn how to evaluate process steps, microstructures, properties and to select proper forming operations to fit the given purpose for all modern applications and metals/alloys.

- Basic principles of solidification and main casting techniques/methods.

- Plasticity theory and background to plastic deformation. Introduction to plasticity of metals, hardening, elastic and plastic deformation, the Bauschinger effect etc.

- Introduction to the main methods/techniques of plastic deformation in metals/alloys (rolling, extrusion, forging, wire drawing, sheet metal forming e.g. deep drawing), thermomechanical processes, reduction and rolling schedules (roll pass design, deformation rate etc.)

- Influence of thermomechanical deformation in the microstructure evolution and control, recrystallization, grain size and microstructure-properties relationships.

- Main defects from deformation processes (e.g. during rolling, extrusion, forging etc.)

- Anticipation of the manufacturing footprint and value chain.