The course provides detailed analysis of the existing integrated methods for the hydrometallurgical treatment of ores using the various hydrometallurgical units which are described in the course “Hydrometallurgical unit operations” of the basic curriculum., including a) production of nickel and cobalt from laterites by extraction with sulfuric acid – alternative methods, b) production of gold from sulfide ores by bio-extraction methods, c) production of gold by extraction with cyanide, d) production of copper by extraction methods in piles, e) uranium production.

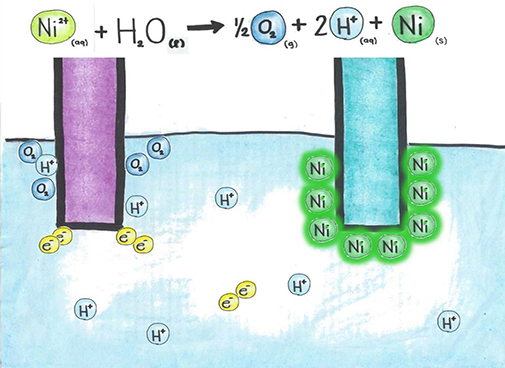

Furthermore, laboratory experiments/tests will be performed by the students concerning all the individual processes of metals recovery from a nickel-iron lateritic sample and ending with the production of a marketable product (metal or hydroxide, or sulphate salt) and their results will be evaluated. The individual steps to be progressively tested include a) Ore sampling and pretreatment, b) chemical analysis using different techniques (aqua regia – fusion – dilution – analysis by Atomic Absorption Spectrometry), c) mineralogy analysis with X-Ray Diffraction and Electron Microscopy, d) ore leeching in tanks at ambient conditions, e) leaching in columns following agglomeration (heap leaching simulation), f) leaching in autoclaves, g) removal of impurities/precipitation in the form of iron hydroxide and goethite – comparison of properties of an amorphous and a crystalline precipitate), h) bioprecipitation of metals as Sulfur compounds using thio-reducing bacteria, k) recovery/separation of elements with organic Solvents, l) recovery of metals from aqueous solution by electrolysis