In the circular economy model which was adopted by the European Union, but also by most countries outside the EU, the key principle is the recycling and recovery of elements, mainly metals, from recycled materials. Undergraduate courses related to Extractive Metallurgy focus mainly on the production of metals and/or their compounds from primary raw materials (ores), with the exception of the production of iron from scrap. This course examines the methods used to produce metals from recycled materials and the various potential secondary product streams after the end of their life cycle. More specifically, the course focuses on the methods for:

- production of secondary aluminium from aluminium scrap

- recovery of lead from car batteries and other lead waste streams

- recycling of copper products

- recovery of basic, precious and critical metals from electric and electronic equipment (WEEEs)

- recovery of precious metals from industrial catalysts and car catalysts

- recovery of metals and graphite from alkaline and other batteries

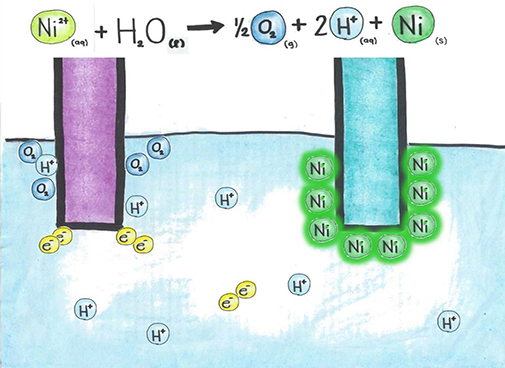

- recovery of technologically important metals from rechargeable lithium-ion (LiB), nickel-cadmium (Ni-Cd) and Nickel–Metal Hydride (NiMH) batteries from digital devices, cars (hybrid and electric) and power storage units.

- recovery of metals from other streams of recycled products